Adaptive Fixturing Techniques for Irregular Castings in Job Shops

Innovations in Fixturing Technology

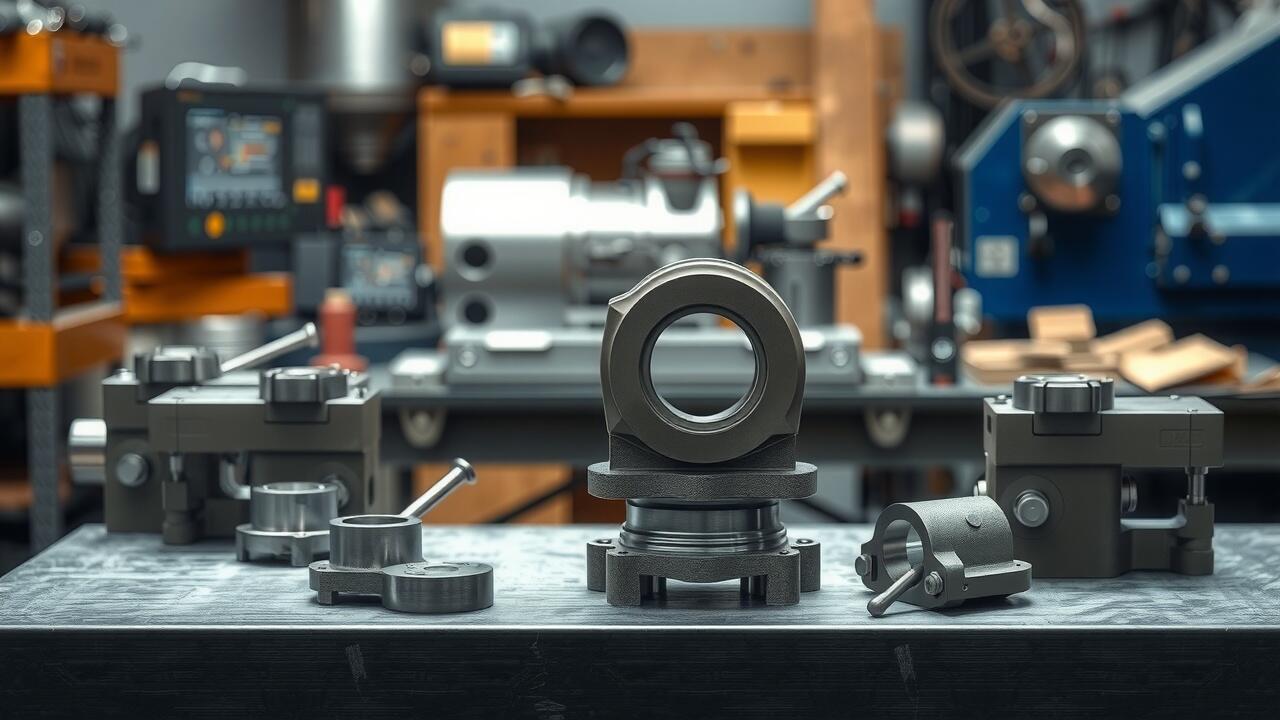

The latest developments in fixturing technology are shaping how job shops handle irregular castings. Innovations such as modular fixtures allow for easy adjustments, making a significant difference in producing custom workholding solutions. For instance, incorporating magnetic fixturing systems can enhance adaptability, enabling quick reconfiguration between different projects. These systems can reduce setup times by up to 50%, an advantage that’s crucial in a fast-paced environment.

Welding workholdings are also embracing advanced features such as predictive analytics and IoT integration. Tools equipped with these technologies can automatically adjust settings based on real-time data, minimizing errors and improving quality. One case study from a mid-sized fabrication shop revealed a 20% increase in efficiency after implementing smart fixturing systems. This not only streamlined the production process but also led to a noticeable boost in overall worker satisfaction, as employees found the new tools more intuitive and easier to use.

What Recent Developments Are Beneficial for Job Shops?

Job shops are increasingly benefiting from advancements in adaptive fixturing technology, particularly with custom welding fixtures designed for unique applications. These fixtures enable precise alignment and support for irregular castings, resulting in reduced rework and faster production times. For instance, a recent case study from a mid-sized machine shop highlighted a 30% drop in cycle times after they implemented adjustable fixtures tailored to their specific casting requirements. With the ability to quickly switch setups, these custom workholding solutions streamline the entire workflow.

Additionally, automation continues to enhance fixturing processes by integrating sensors and smart technology. This innovation allows for real-time adjustments during the welding process, reducing errors significantly. A job shop that adopted such smart welding workholdings reported an impressive reduction in scrap material by 40%. These developments not only increase efficiency but also enhance the quality of finished products, proving that investing in modern fixturing solutions pays off. Embracing these technologies can empower job shops to meet client demands with greater agility and accuracy.

Evaluating Costs and Benefits of Adaptive Fixtures

Evaluating adaptive fixtures, especially in contexts like welding workholdings, requires a careful analysis of both costs and benefits. For job shops, initial investment can vary significantly based on the complexity of custom workholding solutions. For instance, a shop that utilizes specialized custom welding fixtures might incur a higher upfront cost but save approximately 20% in operational efficiency over time. This reduction stems from decreased setup times and minimized errors, which often equate to savings that outweigh the initial expenditure.

Moreover, organizations can enhance their decision-making by applying a structured cost analysis framework. By comparing traditional fixturing methods with adaptive alternatives, job shops can see tangible benefits in flexibility, allowing for adjustments based on project demands. A case study of a medium-sized manufacturer showed a 30% increase in throughput after implementing adaptive fixturing techniques, demonstrating how embracing innovation can lead to more substantial profit margins. Investing in proper analysis tools will enable companies to pinpoint specific areas where adaptive fixtures can improve efficiency and reduce waste.

How Can Cost Analysis Improve Your Decision-Making?

Understanding the costs associated with adaptive fixturing can directly influence decision-making in job shops. Analyzing expenses related to custom welding fixtures helps organizations forecast long-term spending while ensuring they have the right tools for the job. For instance, if a shop evaluates the initial investment against potential gains in efficiency, they might find that increasing their inventory of custom workholding solutions significantly reduces production time. This type of data-driven decision can lead to more informed purchases that align with specific project needs.

Consider a job shop that previously relied on off-the-shelf welding workholdings. The shop conducted a cost analysis and discovered that a bespoke fixture design reduced assembly time by 30% and improved accuracy, ultimately resulting in a yearly savings estimate of $50,000. By applying cost analysis, businesses can allocate resources more effectively, invest wisely in tools, and develop a competitive edge. The goal remains to ensure that any financial investment into new fixtures translates to measurable improvements in both productivity and quality.

Real-World Applications of Adaptive Fixturing

Adaptive fixturing has proven its worth across various job shop scenarios, particularly evident in the automotive and aerospace sectors. For instance, a Michigan-based fabricator implemented custom welding fixtures that adapted to their diverse range of products, achieving a remarkable 30% increase in production speed. This flexibility allowed the shop to handle irregular castings while accommodating short runs without sacrificing quality. They leveraged specialized workholding solutions that maximized efficiency and minimized waste, ensuring that their processes aligned with industry standards.

Another compelling example comes from a leading defense contractor that adopted adaptive fixtures for their complex assemblies. Their strategy included designing custom workholding devices tailored for unique casting profiles, which reduced setup times by nearly 25%. This approach not only increased throughput but also enhanced the precision of welds, crucial for meeting strict specifications. Feedback from operators highlighted the ease of use and adaptability of the fixtures, ultimately leading to a more empowered workforce capable of navigating various production challenges.

What Examples Highlight Successful Implementations?

One job shop recently tackled the challenge of irregular castings by implementing custom welding fixtures tailored to their unique production needs. This facility, faced with a myriad of complex geometries, developed adaptive fixturing that can be quickly adjusted for different components. The result was a 30% increase in productivity due to reduced setup time. Additionally, the enhanced stability offered by these fixtures led to a notable decrease in defects, further optimizing their quality assurance processes.

Another success story comes from a small manufacturer specializing in custom workholding solutions. They managed to improve their workflow by adopting modular fixturing systems that allow for easy transformation in response to changing project demands. Over the course of six months, they reported a 45% reduction in material waste, thanks to better alignment and support for irregular pieces during machining. This approach not only streamlined their operations but also aligned with industry best practices for efficiency and precision in metalworking.

- Improved setup times lead to higher production efficiency.

- Adaptive fixturing can easily accommodate diverse geometries.

- Modular systems provide flexibility to adapt to various projects.

- Enhanced stability minimizes defects and boosts quality assurance.

- These improvements contribute to significant cost savings.

- Better alignment reduces material waste and optimizes resources.

- Innovative fixtures can keep a business competitive in the market.

The Role of Training in Effective Fixturing

Training programs tailored to adaptive fixturing can significantly enhance the efficiency of job shops. For instance, workshops focusing on custom workholding techniques have been shown to boost productivity by 25% when employees are well-versed in the nuances of their equipment. Additionally, hands-on training sessions that simulate real scenarios with irregular castings allow workers to understand the unique challenges presented in welding workholdings. This practical approach fosters a deeper appreciation for the intricacies involved, leading to more effective problem-solving on the shop floor.

Skilled operators are essential for maximizing the potential of custom welding fixtures. A case study from a medium-sized job shop revealed that after implementing targeted training, the accuracy of assemblies improved by 30%, leading to a noticeable decrease in rework and wastage. This focus on skills not only aids individual development but serves as a catalyst for elevating the entire operation. Investing in such training initiatives can yield significant returns, as they prepare the workforce to tackle varying project requirements more adeptly.

How Can Training Programs Enhance Fixture Utilization?

Effective training programs serve as a cornerstone for maximizing the efficiency of adaptive fixturing in job shops. When employees learn the intricacies of custom workholding and how to adjust adaptive fixtures for various irregular castings, they become more confident and precise in their operations. Cutting down setup time is one of the most significant benefits; studies show that skilled operators can reduce fixture setup times by up to 40% through targeted training. This leads to improved throughput and less waste, which directly affects the bottom line.

Incorporating hands-on sessions where workers can explore custom welding fixtures helps them internalize the principles behind adaptive fixturing. Providing them with real-world scenarios mirrors the complexities they face in daily tasks and enhances problem-solving skills. For instance, a shop that offers quarterly workshops on different welding workholdings reported a 30% decrease in assembly errors over six months. Workers who understand how to leverage these tools efficiently become invaluable assets, leading to a more competent workforce capable of tackling diverse projects with ease.

FAQS

What are adaptive fixturing techniques?

Adaptive fixturing techniques are methods used to create flexible setups for holding irregularly shaped castings during machining or manufacturing processes, allowing for adjustments to accommodate different shapes and sizes.

Why are adaptive fixtures important for job shops?

They are crucial because they increase efficiency, reduce setup times, and minimize the need for custom fixtures for each unique part, ultimately leading to cost savings and improved productivity.

How can recent innovations in fixturing technology benefit job shops?

Recent innovations, such as modular fixturing systems and smart technologies, can enhance precision, adaptability, and ease of use, making it easier for job shops to handle a variety of casting shapes without extensive retooling.

What should I consider when evaluating the cost of adaptive fixtures?

You should look at initial investment costs, potential savings from reduced setup times, increased productivity, and the long-term benefits of being able to handle diverse casting shapes more efficiently.

Can training programs really make a difference in using adaptive fixtures?

Absolutely! Training programs ensure that staff are well-versed in the techniques and tools required for effective fixturing, which can significantly enhance fixture utilization and overall operational efficiency.